ECOPROTECT® - Surface Protection Films

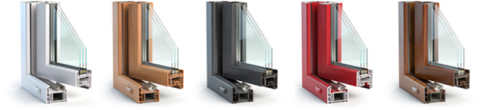

uPVC Door &

Window Profiles

-

Classic White Profile

Classic White Profile -

Foil Laminated Profile

Foil Laminated Profile -

Lacquer Finished Profile

Lacquer Finished Profile

There are numerous risks of damage, scratches, and contamination throughout the production, assembly, storage, transit, and installation phases of your profiles.

Our engineered protective films are tailored to provide a multitude of advantages throughout these processes.

It is clear to us that the number of colours, surfaces, and finishes have only increased with changing times to give consumers different architectural style choices.

Therefore, in response to that, we have developed a wide range of solutions that can cover all your surface and process protection needs. The protection solutions come in various combinations of film formulations, adhesive systems, and printing technologies.

Technology Films are developed to achieve ideal puncture resistance, elongation, and tensile strength properties. Ensuring no fibers or strains

Technology films ensure perfect sliding and COF (friction) characteristics on film surfaces. This guarantees smooth movement on conveyor systems, and effortless grasping, holding, and handling protected products.

Technology Printing & Coatings come with extremely high Scuff Resistance. This guarantees a highly abrasion-resistant film surface so the ink does not fade and “Ghosting” does not occur.

Technology Films come with UV radiation-blocking properties. The film and therefore the profile surface does not deteriorate due to outdoor UV exposure for durations of 3, 6, 9, and 12 months.

| Product | ECOPROTECT® 600A1-X | ECOPROTECT® 600A2-X | ECOPROTECT® 600C-X/E-X | ECOPROTECT® 600A3-X |

|---|---|---|---|---|

| Common Thickness (mic) | 70 | 70 | 70 | 60 |

| Common Colour | White Opaque | Black & White | Black & White | Metallized |

| Adhesive Type | Water Acrylic | Water Acrylic | Water Acrylic | Water Acrylic |

| Tensile Strength (gms/mm2) - MD | 18 - 20 | 15 - 19 | 14 - 16 | 24 - 26 |

| Tensile Strength (gms/mm2) - TD | 14 - 16 | 14 - 16 | 17 - 19 | 23 - 26 |

| Elongation (%) - MD | 400 - 550 | 200 - 400 | 300 - 400 | 400 - 600 |

| Elongation (%) - TD | 750 - 900 | 800 - 1000 | 800 - 1000 | 650 - 850 |

| Adhesion Value (gms/25mm) | 80 - 140 | 100 - 200 | 300 - 500 | 70 - 150 |

Discover our Surface Protection Films range for a variety of Industrial Applications

uPVC Door & Window Profiles