World class facility designed for innovation.

Works

As a manufacturing specialist, Ecoplast has state-of-the-art machinery from leading technology and machine manufactures in the world. Our machines give us the capabilities to delivery an outstanding product and allow us to constantly innovate better methods of production.

We currently have the following facilities available to us at our plant in Valsad, Gujarat, India

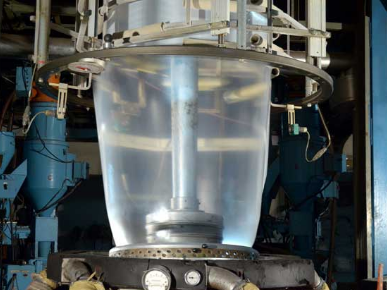

- Latest generation state- of -the art blown film 3-layer co-extrusion plants. The advanced configurations of the plants allow us to process all polyolefins and special polymers to maximize the film performance for various applications. The total capacity is approximately 750 MT per month at Ecoplast.

- Imported wide width long repeat 3 color printing and lamination machine specially suitable for Surface Protection and Masking Application Films.

- Imported state –of- the- art and precision adhesive coating machine fitted with various coating heads to handle diverse adhesives and coat weights

- Precision high speed, slitting & slicing machines to take care of post printing operations.

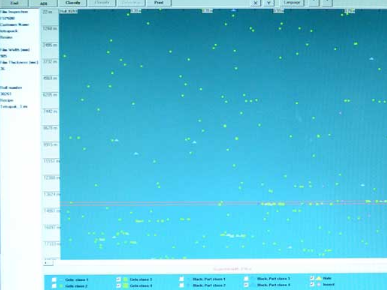

- State of the art quality control equipments.

- Positive air pressure is maintained in the manufacturing area at all times to ensure maximum productivity and excellent product quality. The hygiene is maintained perfectly by ensuring that all plants are dust free.

Technical Services

In a multi-layer PE film, the polymer, the equipment and the process variables combined, determine the level of crystallinity and orientation and in turn the resulting film properties. Thus we take great care in the design of the film so that the customer receives the best product possible. The design of a multilayer film structure is based on pre-determined performance

Characteristics for:

- The film/product compatibility

- The lamination process

- Machinability on the packaging line

- Heat seal characteristics that matches the requirements of the packaging

- Storage (shelf life), handling and transportation conditions

These Technical Service Notes combined with the expertise of Ecoplast’s outstanding engineers, helps customers to derive the critical performance characteristics of multilayer films for a specific application. To systematically evaluate the performance of a trial film roll supplied and to maintain a record of the evaluation, a Technical Service Note titled “Evaluation and Validation of Films” is provided to customers. Based on the results of the evaluation, the film specifications are recorded, a product code assigned for that specific structure, for reference for all future film supplies. This allows the customer to make repeat orders without hassle.

Another team of expert Engineers are always on their foot to design and develop a suitable Surface Protective Films based on the substrate and application of products. It is tailored to meet the specific requirement of the industry, considering various environmental factors. It is professionally designed to protect Glass, Stainless Steel, Aluminium, Carpets, Plastic Sheets, Laminates, metals, automobile parts etc.